Did you know that there are different types of thermoforming services? All of these manufacturing methods are used to create plastic parts and products with lower tooling costs and shorter lead times than injection molding can provide. Thermoformed parts also add value through custom color matching and textured tooling. Plastic thermoforming supports larger part sizes, too.

What’s the right type of thermoforming for your next plastics project? In this blog entry, we’ll examine vacuum forming and pressure forming. Both of these plastics manufacturing methods have their advantages, so contact Gregstrom if you have questions about your specific application.

Vacuum Forming

Vacuum forming heats a plastic sheet until it becomes pliable, stretches the plastic onto a mold, and then uses vacuum pressure to obtain the desired part geometry. Of all the types of thermoforming, vacuum forming is the simplest. In addition to temperature-controlled aluminum tools, wooden patterns and epoxy tools are used.

Vacuum forming supports the use of male and female molds. With male molds, the thermoplastic sheet is placed over the mold. With female molds, the thermoplastic sheet is placed inside the mold. Male molds are used when the inside dimensions of the plastic part are a priority. Female molds are used when outer dimensions are more important than inner dimensions.

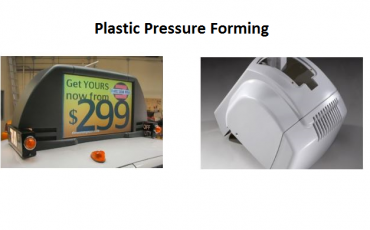

Pressure Forming

Pressure forming is a thermoforming process that heats a plastic sheet until it becomes pliable and then presses it against a mold. To achieve this pressing action, air is removed or vacuumed-out from below the plastic sheet. At the same time, air pressure is applied above the plastic sheet. Once a pressure formed part is cooled, the part retains the shape of the mold.

Like vacuum forming, plastic pressure forming can produce very large plastic parts. With pressure forming, however, part features such as complex shapes, tight tolerances, and integral vents are readily achievable. Plastic pressure forming also supports clean lines, tight corners, and other intricate details. CNC routing or robotic routing is used for parts finishing.

Types of Thermoforming: Making the Right Choice

Gregstrom Corporation is a contract plastic manufacturer that can help you to choose the right types of thermoforming services. We also offer value-added services like design assistance, help with material selection, quality assurance, and assembly and testing. This YouTube video shows the different thermoforming processes, but we encourage you to contact us with questions about your application.