Vacuum formed parts are strong, lightweight, and built for repeated use. Learn how these plastic parts are made and used.

Vacuum forming is the most basic type of plastic thermoforming that heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum to obtain the desired part geometry. Vacuum formed parts do not require temperature-controlled aluminum tools, and wood or epoxy tools can help to control costs for low volume applications.

Advantages of Vacuum Formed Parts

Vacuum forming creates plastic parts that support quick startups and efficient prototyping. Tooling is cost-effective and can be modified quickly to support changes in part designs. Volumes can range from small to large quantities, and vacuum forming supports a wide range of part sizes, shapes, and colors.

Examples of Vacuum Formed Parts

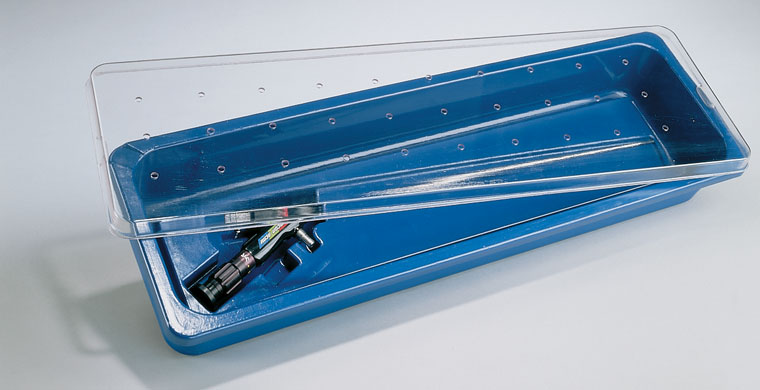

As an experienced vacuum former, Gregstrom Corporation uses vacuum forming to produce plastic parts such as medical instrument case assemblies, trays, covers, taxi tops, and printer assemblies. You’ll find descriptions and pictures of vacuum formed parts on the Portfolio page of our website.

Vacuum Forming Services

Do you need vacuum forming services? For nearly 70 years, Gregstrom Corporation been rotomolding and thermoforming plastics at our Made in the USA manufacturing facilities in Massachusetts. To learn how our pressure forming services can support your application, contact us online or call (781) 935-6600.