Vacuum forming creates cost-effective plastic parts that support quick-startups and efficient prototyping. Learn how this type of plastic thermoforming works.

How vacuum forming works

Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. The simplest type of plastic thermoforming, vacuum forming uses wooden patterns and epoxy tools in addition to temperature-controlled aluminum tooling.

Types of Vacuum Molds

Vacuum forming uses either male or female molds. With male molds, the thermoplastic sheet is placed over the mold. With female molds, the thermoplastic sheet is placed inside the mold. Male molds are used when the inside dimensions of the plastic part are a priority. Female molds are used when outer dimensions are more important than inner dimensions.

The Process: How Vacuum Forming Works

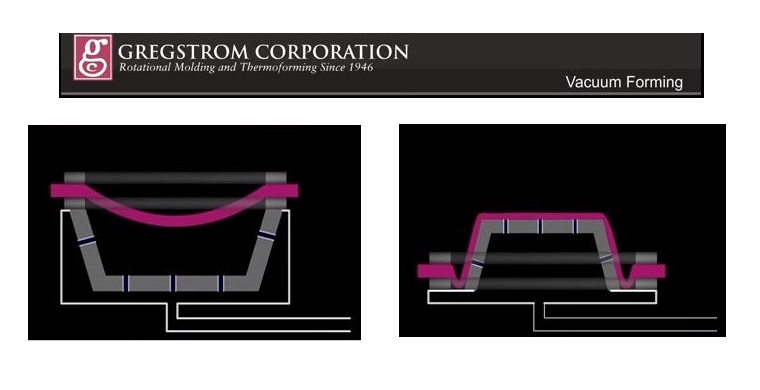

Vacuum forming clamps a thermoplastic sheet in a frame and applies heat until the sheet begins to sag. The frame seals against the mold and vacuum pressure is applied. This causes the plastic sheet to pull against the mold and form the final shape. The bottom of the sagging portion contacts the mold first and tends to retain its thickness. Material in the corners and at the top edges stretches the most and, therefore, thins the most. After cooling, the plastic part is removed from the frame and excess material is trimmed away.

Billow Forming and Plug Assists

Because the final piece is non-uniform in thickness, straight vacuum forming can be supplemented with additional techniques. Billow forming and plug assists are designed to yield more uniform wall thicknesses in the finished part. Plug assists can be used with billow forming, or with straight vacuum forming.

With billow forming, the softened sheet is blown into a bubble with approximately the same surface area as the finished part. The pre-stretched sheet is then pulled against the mold walls by vacuum pressure to produce a part with less pronounced variation in wall thickness. If the depth of draw is especially deep, a plug assist may be used to facilitate an even distribution of material.

Choose Vacuum Forming Services from Gregstrom

Do you have questions about vacuum formed plastics? Would you like to learn more about vacuum formed parts, including as a replacement for metal components? To request a quote or for more information, contact us on-line or call (781) 935-6600.