Plastic thermoforming services from Gregstrom means larger sheet sizes, twin sheet forming, color matching, and a wide variety of plastic materials.

Plastic thermoforming services use large, thick plastic sheets to create demanding parts and products. Gregstrom supports sheet sizes up to 60” x 120” (.040”-.500” thick). We also have twin sheet forming capabilities. Plus, our custom color matching and textured tooling can eliminate the need for painting.

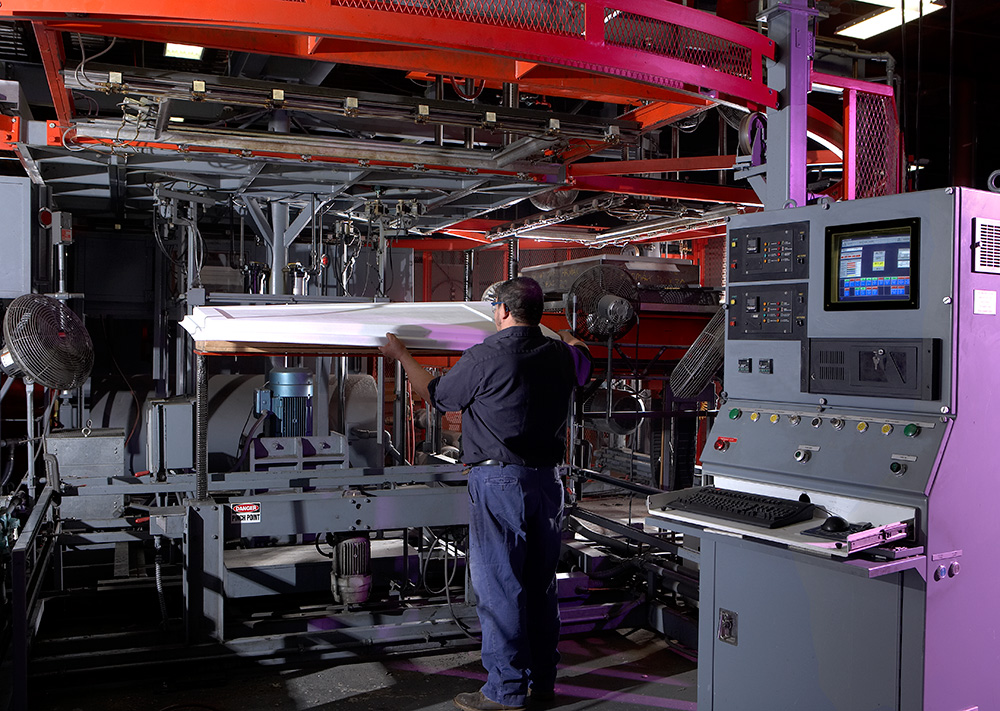

Heavy-Gauge Thermoforming

With sheet sizes that are larger than most of our regional competitors can handle, Gregstrom’s plastic thermoforming services are also diverse. We can match colors based on chips or samples, create thermoformed parts from various plastic materials, and meet the demands of your sales forecasts.

Plastic Thermoforming Materials

Gregstrom forms custom thermoformed parts from plastics such as

- ABS

- Acrylic/PVC

- HIPS

- HDPE

- LDPE

- PP

- PETG

- Polycarbonate

Ask us how textured tooling and plastic sheets in custom colors can eliminate the need for painting parts.

Plastic Thermoforming Services vs. Injection Molding Services

Custom thermoforming from Gregstrom provides lower tooling costs and shorter lead times than injection molding. In addition to machined and cast aluminum, thermoforming tools can be made of wood, epoxy, and other low-cost materials. Tool modifications are cost-effective, and on-the-fly changes support prototyping, short runs, and medium-volume production.

Advantages of Custom Thermoforming Services

Thermoformed parts don’t exhibit the porosity, sink/gate marks, and other undesirable surface conditions that are common to other production processes. Instead, plastic thermoforming provides a blemish-free finish along with fine details.

Thermoforming Plastic Services

Gregstrom Corporation provides three type of thermoforming plastic services.

- Vacuum forming supports quick start-ups and efficient prototyping.

- Pressure forming creates sharp, crisp lines and details; textured surfaces; and formed-in undercuts. Zero degree draft on sidewalls is possible.

- Twin sheet forming produces hollow parts with details on both sides. Twin sheet parts are strong and lightweight, and can consist of dissimilar materials.

Single Sheet Thermoforming and Twin Sheet Thermoforming

Gregstrom’s thermoforming equipment includes shuttle machines and three- and four-station rotaries.

- Shuttle machines process one sheet at a time (single sheet thermoforming) and are ideal for lower-volume production runs.

- Three- and four-station rotaries can hold multiple sheets (twin sheet thermoforming) and are faster and more cost-effective for higher-volume runs.

So whether you need quick-turn prototypes or low, medium, or high-volume production runs, Gregstrom can create the heavy-gauge thermoformed parts that you need.

Learn More About Plastic Thermoforming Services

- Plastic Thermoforming vs. Injection Molding – Tools

- Plastic Thermoforming vs. Injection Molding – Materials

- Plastic Thermoforming vs. Injection Molding – Production and Finishing

- Plastic Thermoforming for Healthcare and Transportation

- Plastic Thermoforming, Reshoring, and Medical Device Manufacturing

- Four Advantages of Thermoforming

Choose Plastic Thermoforming Services You Can Count On

For nearly 70 years, Gregstrom Corporation has been forming and molding plastics at our Made in the USA manufacturing facilities in Massachusetts. To learn how our plastic contract manufacturing services can add value to your application, contact us on-line or call (781) 935-6600.