3D CAD has revolutionized how rotomolded parts are designed and made. 2D CAD was an improvement over blueprints and drawings, but three-dimensional computer-aided design (3D CAD) has transformed the entire product development process. For part designers, the advantages of using 3D CAD software include speed, accuracy, part geometries, physical properties, part stresses, and vendor communications.

Speed and Accuracy

Designers who use 3D CAD software can review highly-accurate digital models before wood patterns are made. Difficult cross-sections are easier to draw, which results in more accurate measurements. All part views are created from the same 3D model. Any changes are easy-to-make. Plus, 3D CAD supports the use of colors that can help non-technical personnel to understand the design of rotomolded parts.

Part Geometries

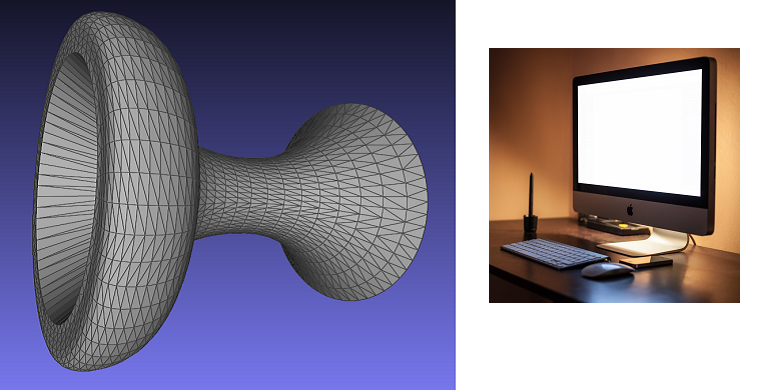

Part tolerances, allowable variations in physical dimensions, can affect part geometry and cause assembly-related issues. By improving the accuracy of a rotomolded part’s design, 3D CAD can support tighter tolerances and the creation of complex shapes. This supports the rotational molding of higher-quality products and the use of CNC or robotic equipment during plastic finishing.

Physical Properties

3D CAD software can calculate physical properties such as weight and volume for plastic tanks and containers. Knowing the exact weight of a rotomolded product allows for more accurate costing in terms of material usage. Plus, mold volume can be calculated to determine if there’s sufficient space for the powdered materials.

Part Stresses

3D CAD supports finite element analysis (FEA), a computerized method for predicting how a product will react to heat, vibration, fluid flow, and other physical effects. By simulating the effects of real-world forces, FEA can help predict whether a plastic part will function that way it’s designed. FEA requires a three-dimensional model, which is another good reason to use 3D CAD with rotomolded parts.

Vendor Communications

Finally, 3D CAD can better communicate design concepts and part details. Designers can submit their 3D CAD files electronically, typically through a vendor’s website in various file formats. There’s no waiting for blueprints or drawings to arrive. Plus, a rotational molder can get the latest version of a part design with just a few mouse clicks or keystrokes

Better Rotomolded Parts

Do you have questions about 3D CAD for rotomolded parts? Would you like to learn more about how rotationally molded parts are designed and made? Then get the Rotational Molding Design Guide from Gregstrom, or contact us on-line.